Carnival Glass 101 | home Quick Reference to Carnival Glass Patterns on This Site

Franks Closet Collection

FRANK’S CLOSET Collection

(The late Frank M. Fenton)

Most long-term collectors will agree that “closet collecting” refers to those who exclusively go out “on the hunt”, buy whatever they “find”, do not associate with the professed collectors, do not belong to or attend functions associated with “professed collectors”, and rarely attend auctions where the majority of professed collectors do their buying.

Quite apart from that, Frank’s CLOSET COLLECTON appears to be elements of production which truly appealed to him; perhaps for their exceptional iridescence, the first of a given shape to have been produced, or any number of other influences which “may have caught his attention”! These items were sold at auction in Dexter City, OH when George Fenton sent factory contents to auction in May 2012.

As with collections owned by each of “us”, the reasons for saving each item was (is) the result of a personal choice and desire. Over the years that we knew and shared ideas, etc. with Frank, we gained the distinct impression that he had a “personal attachment” to the iridized glass. His lack of hesitation to accept invitation to attend/speak before convention groups, eagerness to help us preserve the benefits of the Butler Brothers Wholesale Catalogs, intent upon discussing the manufacturing process, and his warmth of spirit toward all those who visited the glass plant, permeated a business attitude not always found in this world! He combined business and personal pleasure with supreme grace.

Surrounded by a vast field of colored glass displaying craftsmanship in the cut and settings of the artisans who chiseled into cast iron, the designs to be treasured; Frank carried his business interests afar and into the personal aspects which portray his successes.

Although the artisans have long-since passed away, we can continue to marvel at their decantation and Frank’s distinct impressions upon society in general! Looking into the forest that was once a young, vibrant company with high demand for its product, we find a helmsman trying to steer a straight course through a troubled era. The likely effects of nepotism have slowly crept into management, overloaded the profit structure, and torn down the wind sails. Now the ship is headed for the shoals no matter what the helmsman can do.

When a company does not re-invest 55% of its profit back into the company for new products and new methods for making the same product, it will ultimately fail. In the case of a glass plant, the major cost of operating is the natural gas. When the gas company pumps more air into the gas, reducing the BTUs or the heat in the gas, then oxygen must be added to the natural gas. A 1200 gallon tank of oxygen would be required every three days for a small glass plant.

Most small glass plants in West Virginia drill their own gas well. One marble plant I know, drilled a well about 30’ from the plant, on the bank of the Kanawha River in Parkersburg. This innovation keeps competition at bay.

A new conception of a glass furnace would require a concrete esophagus around a fire brick furnace with 3 dams, 8 troughs 1’ x 16’ x 3.5’ to 2’ on the exit end and 8-4’x 4”x 4” enclosed troughs bringing the glass out from the furnace. Start with the 8 primary colors and as the glass gets dirty, change to the next darkest color. This method would extend use over a 4 year period before the furnace would need replacing. Fire brick blisters with heat and turns to cinders, falling into the molten glass, requiring a furnace shut-down every 4 years.

Some glass plants reclaimed the used heat to help fire their furnaces. The old conception used checkers made from fire brick. The new method utilizes steel ingots placed in a pre-determined pattern under the floor of the furnace for the greatest concentration of heat before the flue gasses are allowed to escape. This super-heated 1000 degree air will be sent to an electric driven turbine compressor similar to a jet engine with 8 – 2” x 14” cylinders for natural gas, like a radial engine around the turbine where the super-heated air exhaust and natural gas are expelled under compressed high pressure through a small orifice into the super-heated air. The cylinders will be timed. As one empties, the next one will start and so on……..This super-heated air and gas will enter the furnace above the glass; never directly onto the glass. The gas usage would be cut significantly and not use oxygen. Have you ever looked up at a con-trail and seen puffs about 50’ apart? These are explosions in the jet engine that drive the plane. The same thing occurs with this turbine.

A turbine will be on each side of the furnace and rotate to the other turbine every 20 minutes to allow used gasses to vent up the chimney. The front of the furnace will have eight concealed troughs built like a fan, to allow eight people to work at the same time. As each runner or gatherer sets a dial establishing the amount of glass required for his job, that same amount will repeatedly be expelled. The glass falls into a half mandrel and is picked up on a punty to be taken to the pressman. The same amount of cullet, soda ash, and silica sand is screwed into the other end of the furnace, thus the same amount of glass is always in the furnace.

No one likes to work the night shift, so cut the crew to two men, one for the up-draw and one for a down-draw. Convert one of the 8-4’ x 4” x 4” glass exit troughs with a metal flange on the end, to accept different bolt-on configurations. From the glass cut-off, at the end of the 4’ trough, the glass drops into the half mandrel for regular operations. This configuration will be converted to a down-draw for making colored glass pipe up to 3” in diameter. The same thing would apply for an up-draw, with even larger colored pipe. A platinum ring the size of the outside of the glass pipe ordered, is placed in a ceramic trough and the glass flows around the ring and down and then is pulled to the thickness required with air pressure applied to the center of the hole as the glass begins to flow over the ring.

Colored glass pipe could be used for different applications. Tubing could be cut at different lengths to make goblets, tumblers, etc., then heat the end and form the bottom. The Fry Glass Co. formulas should be used for this type of glassware which can withstand oven temperatures.

These are just a few of the things that with a little innovation might have turned the company around.

Another concept for the second shift would be; on one of the 8 exterior 4’ troughs, bolt on a glass opening ½” high x 14” wide. Extrude the colored glass over a 16” x 48” x 2” deep heated pan containing molten tin, then roll a design into the glass before it cools.

(Dean & Diane Fry—(4-2012)

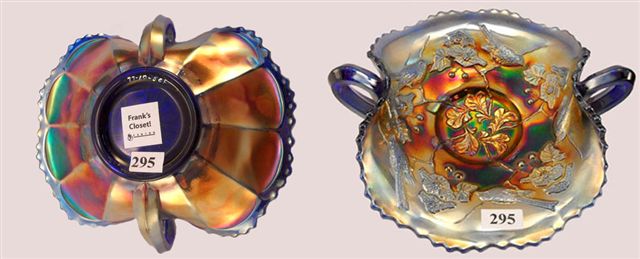

BIRDS and CHERRIES Bonbon - Blue.

Square BIRDS and CHERRIES Bonbon in Amethyst.

CHERRY CHAIN Bonbon - Blue.

9 inch Spatula footed Amethyst DRAGON and LOTUS bowl.

GARLAND Rosebowl - Blue.

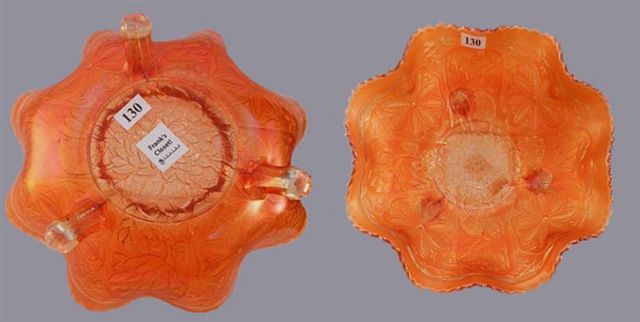

10 -11 inch Ruffled HORSEHEAD Bowl - Marigold.

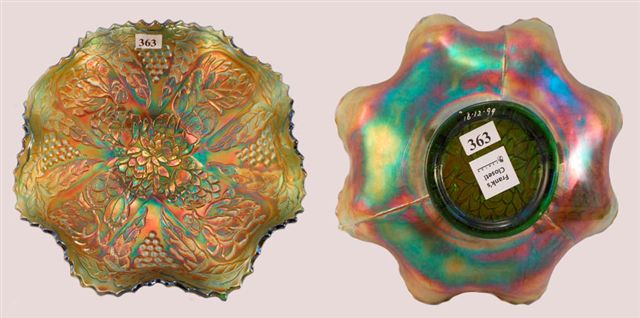

9 inch Green LOTUS and GRAPE bowl.

TWO-ROW OPEN EDGE Banana Boat - White.

ORANGE TREE Breakfast Set - Marigold.

9 inch PEACOCK and URN ice cream shaped bowl - Amethyst.

VINTAGE Epergne - Blue.

Marigold WATERLILY 9 inch bowl.

The heavens declare the glory of God; and the firmament shows His handiwork.

Day unto day utters speech, and night unto night reveals knowledge.

There is no speech nor language where their voice is not heard.

Their line has gone out through all the earth, and their words to the end of the world.

In them He has set a tabernacle for the sun, which is like a bridegroom coming out of his chamber,

And rejoices like a strong man to run its race. Its rising is from one end of heaven,

and its circuit to the other end; and there is nothing hidden from its heat. (Psalm 19:1-6)

Psalm 191-14 describes ways God can speak to us. First, God speaks in the skies—(vv.1-6)

The stars and moon in the night sky point to a Creator.

Paul tells us that His eternal power and Godhead are clearly seen by the things that are made (Rom. 1:18-25)

God also speaks through Scripture (Ps. 19:7-14)

The Bible…. written by 40 different authors over 1,500 years in 3 different languages

tells us of our sin and God’s plan of redemption.

Should you care to contact the Frys, their email address is:

Search Carnival Glass 101

back to Carnival Glass 101

Our other sites you may enjoy:

Everything you EVER wanted to know about Indiana Glass

Great Reference for Newer Carnival Glass.

Complete Glassware Catalogs Available to Download

Questions? Comments? Suggestions? Broken Links? Corrections?

Your Friendly Webmaster is here to help!