Carnival Glass 101 | home Quick Reference to Carnival Glass Patterns on This Site

Stippled N Grape and Cable Revised

“STIPPLED” GRAPE & CABLE”

By Jerry & Carol Curtis

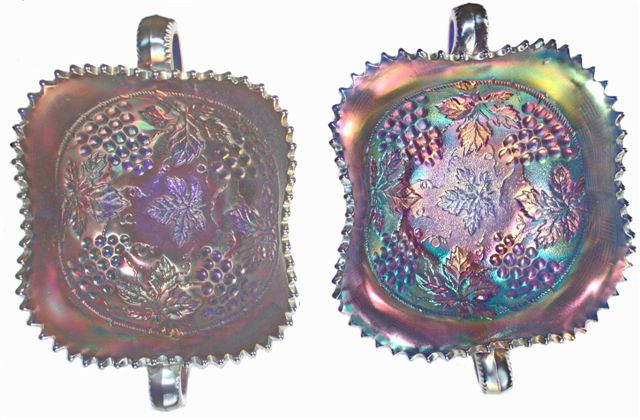

Northwood GRAPE & CABLE Bon-bons - Stippled & Unstippled in Blue.

Left - N. GRAPE & CABE Bon-bon in Blue - Chisel #5 applied for Stippling.

Right - Number 5 Chisel.

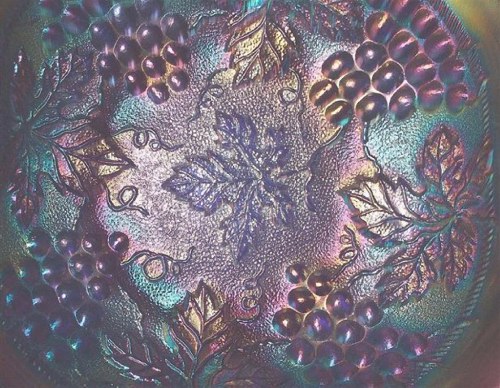

Green N. GRAPE & CABLE 9 in. Plate with Stippling extended over all but Grapes.

This Article is more about the “process” rather than the piece. Recently, Carol and I purchased a beautiful Grape and Cable Bon-bon by Northwood in Blue. We noticed the piece was “stippled” and that made it even more appealing to us. As most of us do after buying a piece of glass, we immediately went to Mordini’s auction report to see how we had fared with our purchase. I was certainly surprised at my findings. In checking back from the current year to 1988, I found that while there had been numerous sales of the blue bon-bon of the regular variety, [22 reported], there had been only [2] of the Blue Stippled Bon-bons reported sold during the same [11] year time frame. Also, the stippled variety of any pattern seems to be bringing a higher price when sold. Being of an inquisitive nature, I decided to try and find out a little about stippling. Where else does one go to have a process explained to him but Frank Fenton? I contacted Frank and asked him the following questions regarding the “stippling” process. I formatted the questions with Mr. Fenton’s replies in “quotation” marks.

1. Could you explain the process used by the early Fenton Company to achieve the stippling process? Is that process still being used today?

“The process that we use today is essentially the same process as that used many years ago. We have many more tools and lots of up-to-date things we can do, but in general the stippling is done about the same way as it has always been done. What happens is that the mould maker has a special tool and he stipples by placing one end of the tool on the cast iron mould [or plunger] and hitting the other end of the tool with a hammer. He repeats this process many times and the result is a whole bunch of little dots. They may be circular, triangular, or square dots. He puts those in a random manner in the area that is supposed to be stippled. If we want a special texture pattern like that we used on our Carnival Glass heart-shaped candy box [that’s a new one that came into the line in the early 70’s], that kind of pattern, which is a regular pattern of detail, we need to send the piece to have the pattern etched on the item. This is something they never thought of doing many years ago. But the stippling you’re talking about is still being done the same way”.

2. Why were some pieces stippled while others were not?

“Now what could be the reasons why somebody stipples a piece?”

“The mould-maker or designer wants a different texture from the shiny surface of the Glass, so he stipples a portion to get the texture. This was often done on clear crystal pieces, usually on the outside of the glass, but occasionally on the inside. It’s essentially an effort to create some variety in the design and to show up the plain surface better by having the stippled area around it. Sometimes we do the stippling in the patterned portion and leave the plain part of the piece shiny.

As you suggest, it could also have been done in order to have the iridizing appear differently on the stippled portion than it does on the shiny portion. If the stippling is on the outside of the piece, it may have been done in order to cover up or eliminate the “settle wave”. When the glass is first dropped into the mould, it settles before the plunger has a chance to get to it. Right at that point, when the plunger hits it, the glass moves and makes a little wave that goes all the way around the piece. Most pressed pieces have some settle waves and we don’t worry about them. But sometimes stippling will cause that not to happen. In rare cases, it may be done because there was some damage to the mould and they decided to stipple the surface in order to cover the damage. This could happen either on the mould surface or the plunger surface [which is the interior of

the piece]. There are many old patterned glass pieces made primarily in crystal that were stippled in certain portions of the piece in order to give it a frosted effect, something like the Posies and Pods tumbler or pitcher made by Northwood. I don’t think that pattern ever got into the Carnival Glass trade. I just looked in Dave Doty’s book and don’t find it listed under that name. The Lightening Flower pattern by Northwood is another one that comes to mind that was probably made first in crystal. That one is shown in Doty’s book”.

3. Was this a planned result of the glassmakers or was it purely accidental?

“I’m sure the stippling is a planned result of the mould-maker’s or glassworker’s

process. I can also imagine that there would be times when the item would be made

without stippling and then the manufacturer would look at it and say, let’s stipple this

portion to improve it. We sometimes do that. Most of our moulds are made from a

drawings, and sometimes the glass doesn’t look like the drawing indicated it was go-

ing to look. When we see it in glass, we may decide we need to do something else

to make the pattern more distinct or to improve the general quality of the piece.

That’s where stippling comes in”.

Well there you have it. Many thanks to Frank Fenton for sharing this information with us. It is always very meaningful to us all when we may call on such an experienced person as Frank Fenton and have our questions answered. As you can see from Frank’s responses, the stippling process was an added detail in the production of Carnival Glass. Something that Mr. Fenton said in one of his responses kind of stuck in my mind; the second question and his 4th response about mould or plunger damage. Perhaps the stippling effect on Northwood’s pieces came about in the latter years of production, when the moulds were getting old and worn from so much use. Perhaps the stippling effect was an added feature to cover up that mould or plunger damage. That might explain why there were relatively fewer Grape and Cable pieces that were stippled, for it may have been added just prior to the closing of the Northwood Company. (Revised: 10/15/11)

A good name is to be chosen rather than great riches,

loving favor rather than silver and gold.

The rich and the poor have this in common, the Lord is the maker of them all.

A prudent man foresees evil and hides himself,

but the simple pass on and are punished.

By humility and the fear of the Lord are riches and honor and life.

Thorns and snares are in the way of the perverse;

he who guards his soul will be far from them.

Train up a child in the way he should go,

and when he is old he will not depart from it.---(Proverbs22:1-6)

Should you care to contact the Frys, their email address is:

Search Carnival Glass 101

back to Carnival Glass 101

Our other sites you may enjoy:

Everything you EVER wanted to know about Indiana Glass

Great Reference for Newer Carnival Glass.

Complete Glassware Catalogs Available to Download

Questions? Comments? Suggestions? Broken Links? Corrections?

Your Friendly Webmaster is here to help!