Carnival Glass 101 | home Quick Reference to Carnival Glass Patterns on This Site

Windflower Pattern

WINDFLOWER Pattern

By: Jerry Kudlac-10-14-11

Made by Dugan / Diamond Glass Company

Introduced c1911 by the Dugan firm.

Appeared in 1914 Butler Brothers Catalog as iridized and opalescent glass

D/D p128, 129

Glass:

Non-Iridized Opalescent – white and blue opalescent, Black and Pink

Iridized - Most common colors of glass: Marigold – crystal, Blue and Amethyst

Uncommon colors: Amber, Lavender, smoky lavender, smoky blue, horehound,

Vaseline, marigold over pink glass - (Afterglow) marigold over pastel green

glass - (Afterglow) Oxblood or Fiery amethyst.

Shapes:

Plates 9 – 9 1/4'” in diameter (marigold & blue)

Bowls 8 ¼ - 8 ½ “ in diameter - 23.7583 sq. inches.

Two concentric circles divided into 36 squares.

There are 18 panels with two squares per panel.

Two sprigs with flower and leaves in a circle, but not identical.

On one sprig the first leave in curved in about a half circle (left) in the

other sprig (right) the first leaf is straight.

The flowers cover approximately 40% of the pattern area and some of the

pattern is also stippled.

The background is stippled and covers approximately 60% of the area

or 14.2544 sq. inches.

There are approximately 1520 stipple marks per sq inch.

The background has approximately 22,000 stipple marks.

Stipple design was applied by hand with chisel and hammer in radon

fashion. Individual stipple strikes, as well as over-strikes, results in

arrangements of stipple marks that are as unique as a “fingerprint”.

Duplicating 22,000 stippling marks, over-strikes and arrangement by

hand in exactly the same manner on another mould would not be possible.

With these facts, the “fingerprints” can be used as a tool to determine if

there was more than one mould (plunger) used to make the Windflower pattern.

PHOTOGRAPHS:

(Photo was converted to black and white to better view the topography of the design.)

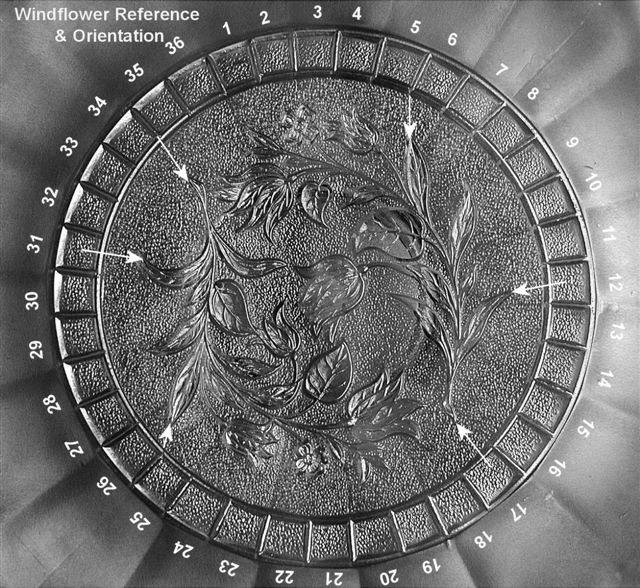

1. Windflower pattern:

Two concentric circles with 36 squares or sections and 18 radiating panels

(two squares per panel)

Two arrangements of flowers (right and left) on a stippled background

The Windflower pattern has approximately 1520 stipple marks per square inch or approximately 22,000 stipple marks in the background

See Windflower Reference for orientation of the design.

Right flower arrangement

SQ #5 – third leaf on stem points between sq 5 & 6

SQ#10 – Large Flower in center of design

SQ#12 – First leaf on stem is straight

SQ#17 – Stem points to center of sq 17

Left Flower arrangement

SQ#34 – Stem point to line between sq 34 & 35

SQ#31 – First leaf on stem is a semi-circle shape

SQ#25 – Third leaf on stem points between sq 25 & 26

No large flower in center of design.

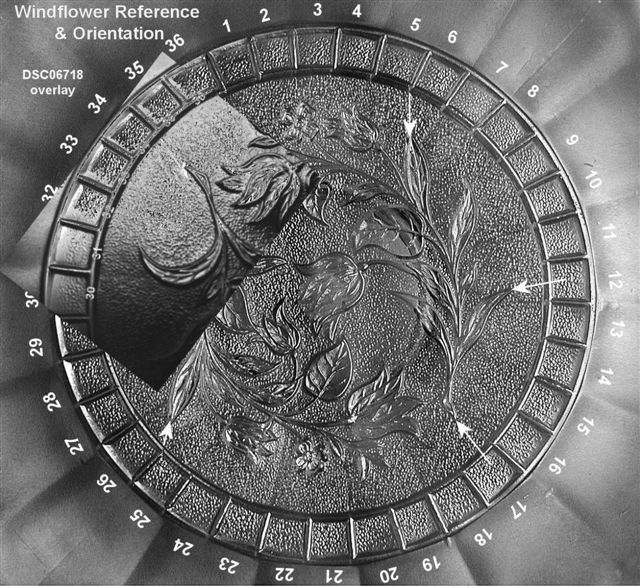

Windflower photo overlay on Reference.

2. I converted your photo to black and white and placed it as a transparent over-lay on the reference photo to show it orientation on the Windflower pattern.

Comparison of photo DXC06718 with Reference

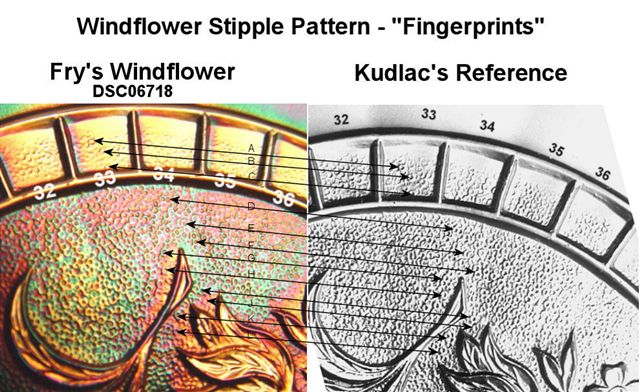

3. I used your photo and my reference photo to locate identical stipple marks that can be used as a “Fingerprint”. This is a composite photo showing side-by side comparison of the same stipple marks that occur in the same location on the two different items which indicates that they were made with the same plunger.

(For first time observers this may take some concentration to see them. It helps to have the same angle of light on both photos to see the stipple marks.)

This photo an example of what can be done. I always look at four to five areas in different locations within the pattern. I did the same comparison with the other photos you sent and found identical stipple patterns in your photos and my reference.

Windflower Comparison – Arrows labeled with letters.

A, B & C – Three large stipple marks always appear in square 34 in the same place.

(They look like small volcanoes)

D – Pair of large stipple marks

E - Pair of stipple marks with an over-strikes – one is misshaped.

F – Chain of three large stipple marks

Continued on next page

G & H – Six or more large stipple marks forming a chain

I – Pair of large stipple marks

J, K & L – Single Large Stipple marks.

Large stipple marks on the glass result from deeper stipple impressions in the mould. The reverse stippling or the mould stippling can be viewed by making a latex mold of a sharply impressed glass pattern. This helps to see the stippling from both points of view.

Additional Evidence for one plunger used in the Windflower pattern

46 different colors and shapes of the Windflower pattern have been compared (with duplicates). All can be identified as being made from one plunger using five or more “fingerprints” from various locations in the pattern.

James Measell, Historian, Fenton Art Glass Co. stated that he was hired to inventory the L.G. Wright moulds in January 1997 and reviewed it again in May 1999 when it was sold. No Windflower plunger was found. He has also reviewed the inventory of Fenton moulds and the Windflower plunger is not in their inventory.

There has not been a report of this pattern being made in contemporary glass.

The conclusion is that there was only one plunger and it was either destroyed in the fire of 1931 or later sold for metal salvage.

Stippling

Stippling was added to pressed glass moulds to enhance the design, background or to refurbish a mould. Stippling gives an additional textured surface to the final pressed glass which also allows the applied iridescent spray to accumulate in various thicknesses on the surface of the glass. The textured surface causes more light interference and the various layers of the spray results in more colors in the iridescence than would be evident on flat glass surface.

The stipple marks were applied to the plunger or mould by hand using a chisel to punch the stipple marks into the metal. The size and shape of the stipple mark is dependent on the type and/or shape of the chisel and the amount of pressure used to punch the stipple mark into the metal of the plunger or mould. A deep stipple mark results in a slightly larger stipple pattern in resulting pressed glass. Chisel over-strikes result in the stipple marks being misshaped – flatten or oblong, etc. Occasional vacant spaces can be found between the stippling marks. All of these occur at random as single, pairs, chains or groups of slightly larger stipple marks and vacant spaces in the pressed Carnival Glass and are as unique as a “fingerprint”. These “fingerprints” can be used as a tool to determine if there was more than one mould (plunger) used to make the same pattern.

All of the described variations in stippling can be found in various patterns or backgrounds of Dugan / Diamond, Northwood, Millersburg and Fenton Carnival Glass.

FYI Documentation:

Iridescence principles and its appearance were described by Littleton of Corning Glass Works in a patent application in 1931 (Patent 2118795 awarded in 1938) in which he stated that the color of iridescence was depended on the thickness of the coating (on flat or smooth glass). Additional patents awarded to Corning in 1947 (2522531) and in 1951 (2564706) also described the measurement of the coating thickness and the predictability of the iridescent color which is caused by interference of light known as Newton’s rings. (“A Treatise on Light” by R.A. Houstoun, Longmans Green & Co Ltd. (1938) page 187).

Comment: Early iridescence of Art glass was on a flat surface, but glass makers found that using a design or pattern in pressed glass created a textured surface that enhanced the iridescence. The textured surface was created using a design, floral pattern (ex. Grape leaves, flowers, etc.) animals (peacocks –feathers) and geometric designs. The designs were also enhanced by adding stippling (grape leaves in Grape & Cable) and (geometric – Cobblestone) to the design or background. Each of the designs, patterns, and stippling creates a textured surface with “hills and valleys” which trap the spray which accumulate in various thicknesses and both of which results in more light interference and iridescence than a flat surface.

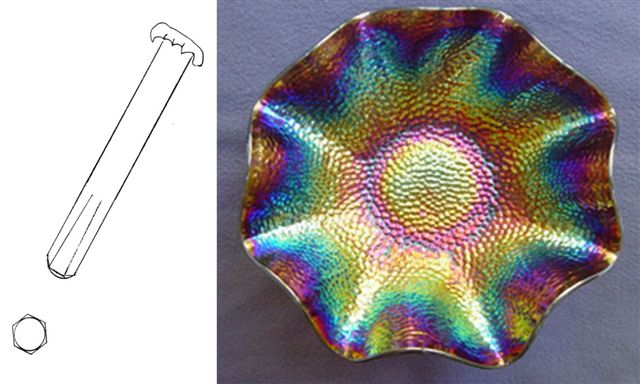

Round Chisel used to Stipple COBBLESTONES 9 in. Bowl.

The Fry’s added this photo of the Cobblestones bowl and the drawing of appropriate chisel for creating the bold geometric design. These 8 ½-9 ½” bowls offer the Arcs pattern exterior. Marigold bowls are quite scarce as compared to purple. A couple of blue examples are known. Helios and amber are additional bowl colors. A 9” flat plate is said to exist in purple. Overall, the pattern is not easily obtained, as compared to many other Imperial designs.

Chisel #5 used to create stippling on Mlsbg. ROSALIND.

The Millersburg Rosalind/Dolphin bowl is a prime example of overall stippling. It probably offers more than any other pattern produced by that company.

(10-17-11)

Should you care to contact the Frys, their email address is:

Search Carnival Glass 101

back to Carnival Glass 101

Our other sites you may enjoy:

Everything you EVER wanted to know about Indiana Glass

Great Reference for Newer Carnival Glass.

Complete Glassware Catalogs Available to Download

Questions? Comments? Suggestions? Broken Links? Corrections?

Your Friendly Webmaster is here to help!