Carnival Glass 101 | home Quick Reference to Carnival Glass Patterns on This Site

Glass History

GLASS HISTORY

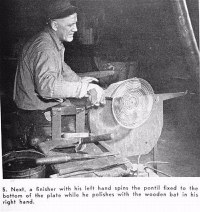

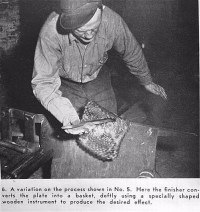

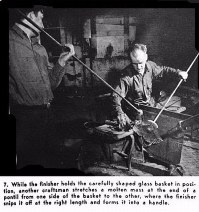

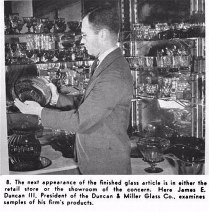

While neither Duncan & Miller nor Tiffin Glass Companies are known to have produced carnival glass within their respective factories, other colored glassware and stemware have a definite place within the world of carnival glass collectors. The photos shown offer insights into the skills of attaching stems to goblets, wines, etc., examples of which we see and use from time to time.

We sincerely trust that you find meaning and significance to preservation of glassmaking as an art, giving it the rightful place it so well deserves in the history of worthwhile artistic endeavors.

DUNCAN & MILLER Glass Company – 1872 – 1955

Details from October 1941 - The Pottery and Glass Salesman

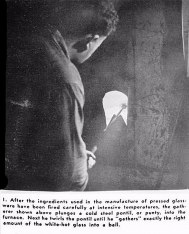

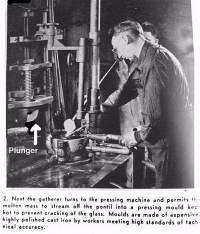

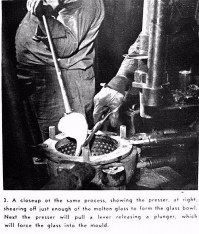

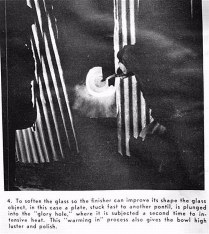

The Manufacture of Hand Pressed Glassware

The majority of the nation’s glass plants have been situated in the Pittsburgh, PA, WV., OH area, for it is the heart of natural gas and bituminous coal, used to create the hottest of fires. Fine silica sand, a basic ingredient for many types of fine glass, is also present in numerous beds, while other essentials, such as limestone, soda ash, salt cake and borax are all to be found in this eastern area of the Country.

The Duncan & Miller Glass Company goes back to 1865, when two brothers, James E. and Harry B. Duncan, launched the firm of George Duncan & Sons Company, situated at 10th and Carson Street in Southside, Pittsburgh in 1872. At that time, the Southside of Pittsburgh was a hub of barge transportation providing silica sand and potash required to make glass. Descendents of generations of skilled glass makers also called the Southside their home. Pittsburgh was a leader in glass production from colonial times, having attracted skilled workers from the European glass centers.

In 1874 a young German designer of considerable talent, Ernest Miller, joined the firm. He had worked through many stages in the glass industry for twenty years, so became a famous designer for the company for the next fifty-two years.

From 1890-1892, the firm was company D in the United States Glass Company combine. That plant was destroyed by fire. George Duncan had died in 1877, leaving direction of the company to his son James. He selected a site for the new factory on Jefferson Avenue in Washington, PA. That new plant was completed on January 3rd, 1893. The 16 pot “Deep Eye” furnace was fired up, with the first pattern made on February 9th, 1893.

Seventy employees of the old Pittsburgh factory relocated to Washington, PA, with many of them remaining employed for fifty to seventy years, creating brilliant polished examples of excellent design quality.

The period from 1893 to the closing of the plant in 1955 is known as the Duncan-Miller era. Ernest Miller was made a partner in 1900. At the death of James Duncan Sr. in 1900, his younger brother Harry B. Duncan became President and served until his death in 1925 when James Duncan Jr. followed as President.

Closing of the plant came on August 30th, 1955, when moulds, machinery and equipment were sold to United States Glass Co., with headquarters in Tiffin, Ohio.

Click on each picture for a larger view.

Click on each picture for a larger view.

TIFFIN GLASS History

Following more than a year of negotiations in various communities to determine a site for a new factory, A.J. Beatty & Sons glass factory of Steubenville, Ohio, made the announcement in July 1888, that a new factory would be built in Tiffin, Ohio. They offered five years of natural gas, $35,000 in cash, and land valued at $15,000. A three-furnace glass factory located at the corner of Fourth Ave. and Vine Street began construction in September 1888. Operations began on August 15, 1889. Production capacity was reported to be 500,000 pressed tumblers per week.

A.J. Beatty & Sons merged with United States Glass Company on January 1, 1892, becoming one of nineteen factories in that large corporation. Tiffin factory was designated Factory R. Less than two years later, Factory R was destroyed by fire. A new factory was constructed in Tiffin in return for two additional years of free natural gas.

Response to customers’ demands brought about a gradual shift from pressed to blown tableware during the early years of the 1900s. Glass items were identified with a paper label having USG intertwined within a gold-colored shield. Commercial ware continued to be marketed under the United States Glass Company name until Sept. 1927. Following that date, household goods were identified with a gold paper label with TIFFIN superimposed on a large “T” within a shield.

Other factories within the U.S. Glass Conglomerate were forced to close during the Great Depression of the 1930s, but Factory R survived. In June 1938, offices of the U.S. Glass Company were transferred from Pittsburgh, PA to Tiffin with C.W. Carlson as President. With the advent of 1940, all glassware was being marked with a Tiffin label; but the official name of the company remained U.S. Glass Co. through 1962.

During the 1940s, major changes occurred in the tastes of the American public, resulting in transition from colored stemware to crystal stemware. Fewer items were produced in each stem line. Focus of Tiffin’s production continued to be stemware; however, a new line of modern designs contributed to the prosperity of the Tiffin factory. Introduction of a Swedish Modern line by Mr. Carlson in 1940 proved profitable. In May 1946, the name was changed to Tiffin Modern, in order to clarify that the free-form glassware designs were American made. Buyers’ interest in the free-form stemware continued into the 1960s.

Purchase of numerous Duncan and Miller Glass Company molds and equipment occurred in 1955. Production of several popular Duncan patterns continued at the Tiffin and Glassport factories from 1956 until closing of the Tiffin facility in 1980.

Serious financial difficulties arose within the corporation, in 1958, resulting in the sale of assets to a New York investment firm. When business conditions did not improve, a second sale took place in March 1961 to Brilhart Plastics Corp. of Mineola, N.Y. Bankruptcy was declared in 1962; however, the Tiffin factory remained open until early 1963, when four former employees-Paul Williams, C.W. Carlson Jr., Ellsworth Beebe, and Bea Platt bought the plant and renamed it Tiffin Art Glass Company. Incorporation took place May 1, 1963. Sept. 16, 1963 was the start-up date for the new Tiffin venture. This transaction marked the end of the United States Glass Company. While a great loss was incurred on Aug. 3, 1963, when the Glassport facility was destroyed by a tornado, business improved with $2,000,000 in annual sales.

June 4, 1966, the company was sold again to a major corporation, the Continental Can Co., in exchange for 6,462 shares of Continental common stock. The company name was changed to Tiffin Glass Co., Inc. Stemware remained the focus of production during these years, with blown and pressed ware also manufactured.

In Dec. 1968 the factory changed hands again, going to another large corporation, Interpace, parent company of Franciscan, Shenango, and Mayer China companies. It continued to be known as Tiffin Glass Co., but in addition to using the gold Tiffin shield sticker, Interpace began applying a paper label, “Franciscan Crystal,” placed on selected stemware lines in May 1969. This practice continued for two years. Interpace introduced several new stemware lines to compliment their china dinnerware patterns.

Tiffin factory supplied a variety of stemware patterns to several companies for private distribution as early as 1930, continuing into the 1970s. Retail outlets such as Sears and Roebuck, Montgomery Ward, Tiffany’s, Macy’s, Colony House, Royal Medallion, Nancy Prentiss, American Manor, and Reynolds Crystal were all regular buyers. American Manor and Reynolds Crystal were subsidiaries of Interpace Corp., the parent company of Tiffin Glass, from 1969-1979. Several new colors in stemware were introduced during this ten-year period, designed to coordinate with Interpace’s Shenango China.

The factory was sold for the last time in May 19, 1979, to Towle Silversmiths, operated as Tiffin Crystal, a division of Towle Silversmiths. When the furnaces were shut down on May 1, 1980, many collectors considered it to be the end of the Tiffin Glass Company. The Outlet Store and a decorating shop remained open until Oct. 1984, when the facility closed permanently. Towle donated the factory and land to the city of Tiffin in exchange for a $1.1 million tax write-off. The city offered the property free to any company promising to bring 100 jobs to the city. Unable to find a tenant, the city demolished part of the factory in late Dec. 1985 and Jan. 1986. Towle continued to sell Tiffin Glass stemware via mail order, including the popular pattern Palais Versailles, through 1990.

After production ceased in 1980, molds were dispersed and Russell Voglesong of Summit Art Glass Co., Ravenna, OH, acquired the Tiffin shield trademark mold.

Tiffin Glass Collectors Club purchased this mold in 1991. To date, the log has been reproduced in five colors; pink, cobalt blue, red, plum, green and yellow (vaseline), some having satin or iridized finishes.

Tiffin Glass products were identified with various paper labels through the 1970s. During that same timeframe, some products were marked by application of an acid stamp of the Tiffin shield trademark.

-History- Courtesy of the book ‘40s, ‘50s & ‘60s Stemware by Tiffin-by Ed Goshe, Ruth Hemminger, and Leslie Pina

Should you care to contact the Frys, their email address is:

Search Carnival Glass 101

back to Carnival Glass 101

Our other sites you may enjoy:

Everything you EVER wanted to know about Indiana Glass

Great Reference for Newer Carnival Glass.

Complete Glassware Catalogs Available to Download

Questions? Comments? Suggestions? Broken Links? Corrections?

Your Friendly Webmaster is here to help!